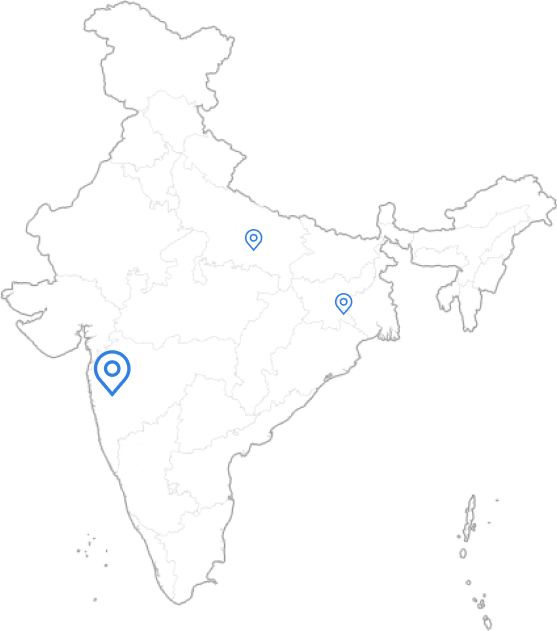

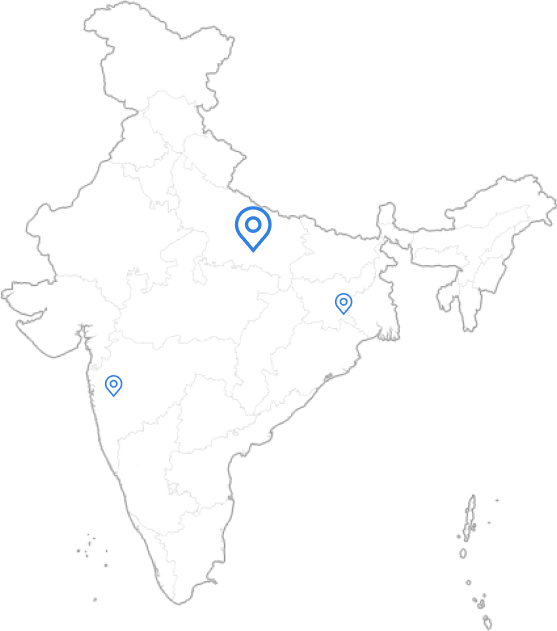

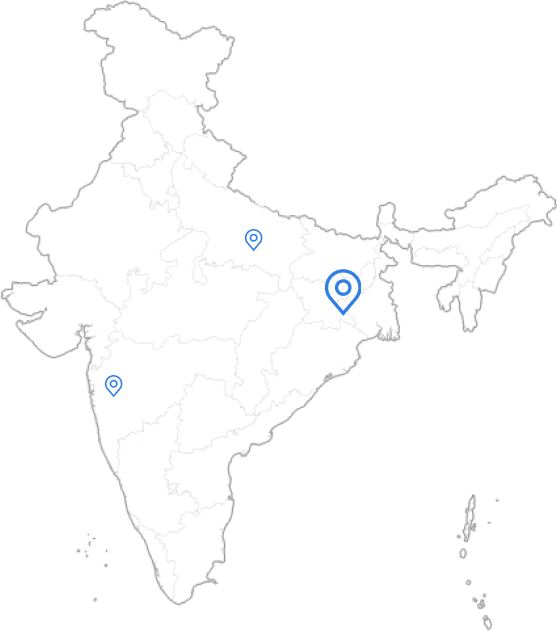

The Biggest Production Capacity in India Today

Tata Motors trucks are manufactured at our state-of-the-art large production facilities across the country. Know more by clicking on the locations below:

Tata Motors trucks are manufactured at our state-of-the-art large production facilities across the country. Know more by clicking on the locations below:

Established in 1992, Tata Motors Lucknow is one of the youngest production facilities of the company and was set up to meet the demand for commercial vehicles in the Indian market. The state-of-the-art plant is strongly backed by an Engineering Research Centre and Service System to support and cater to the complexities of automobile manufacturing with latest technology. The Fully Built Vehicle business, which is one of our fast growing business segments, is also established in Lucknow. Our Lucknow plant rolls out commercial vehicles and is specialised in the design and manufacture of a range of modern buses as well as chassis including Low-floor, Ultra Low-floor, CNG & Rear Engine Buses. The Lucknow facility also specialises in manufacturing HCBS (High Capacity Bus System) buses.

Established in 1945, the Jamshedpur unit is spread over an area of 822 acres and happens to be the company's first manufacturing unit. The Jamshedpur plant's engine factory is responsible for the in-house manufacture of Tata 697/497 naturally aspirated and turbocharged engines, and the 6B series engines manufactured at Tata Cummins. HV Axles Ltd., a wholly owned subsidiary of Tata Motors, manufactures front steer axles - both live and normal, rear drive axles and dummy/ trailer axles. It is currently the sole supplier of large bus axles to the Jamshedpur and Lucknow plants of Tata Motors. The company also manufactures all major axle components such as front axle beam, stub axles, front & rear wheel hubs, differential, axle gears (crown wheel, pinion, bevel gear & shaft gear), banjo axle beam, swivel heads, constant velocity shafts etc. HV Axles Ltd. is a leading manufacturer of automotive transmissions, components, gearboxes and engineering applications for a wide range of medium and heavy commercial vehicles.

The Pune unit is spread over two geographical regions - Pimpri (800 acres) and Chinchwad (130 acres). It was established in 1966 and has a Production Engineering division with one of the most versatile tool making facilities in the Indian subcontinent. Our Pune facility rolls out all makes of Tata Engines in both diesel and CNG fuel options, and also has a dedicated assembly line for LCV Bus chassis. It is engaged in the design and manufacture of sophisticated press tools, jigs, fixtures, gauges, metal pattern and special tools, as well in the design of models for development of new ranges of buses and coaches. Industry experts rate the fully automated Foundries at Chinchwad and Maval among the best worldwide.